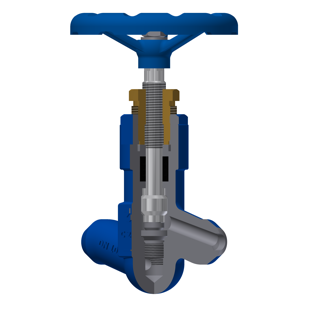

Design

- Forged body

- Rising stem

- Needle type disc

- Seats are integral or welded on ring which is then securely screwed into the body

Applications

- Power plant

- Chemical

- Petrochemical

- Refining

Media

Depending on the valve materials:

- water

- steam

- gas

- oil and oil derivates

- other non aggressive media

Pressure and temperature

- Pressure up to 630 bar

- Temperature up to 600 °C

Materials

- Carbon, heat resistant alloy and stainless steels

Advantages

- Long service life

- Respect to emission standards

- Easy handling and maintenance

- Stem packing replacement in working conditions

Options

- Seats and sealing made of elastic materials

- Socket welding (SW) or Butt welding (BW) ends

- Internal or external threaded ends

- Other paint finishes are available upon customer’s request

Testing

- Every produced valve was tested according to EN 12266

Interested in this product?

Raise a nonbinding request now!